Frozen Can Line, With Pasteurizer, Filler, Coder, Packer, Seamer, Palletizer, #5991536

Frozen Can Line, With Pasteurizer, Filler, Coder, Packer, Seamer, Palletizer, #5991536

Location:Washington

Available quantity:1

Description

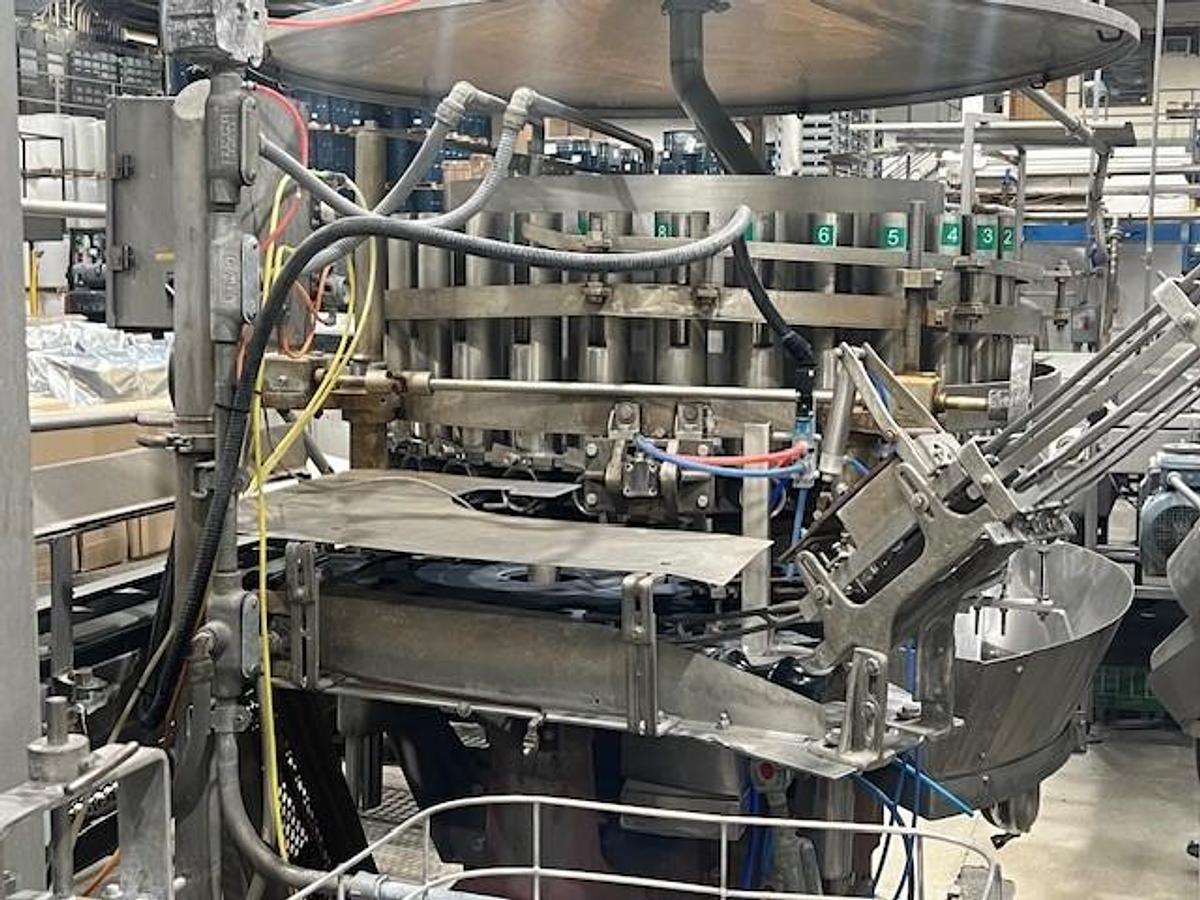

Complete frozen food canning line for round metal cans, including depalletizing, conveying, pasteurizing, filling, coding, packaging, and palletizing. Line components include DE palletizer and can cable rails feeding a rotary can filler (Elmar Model RPE 628-LH), paired with a can seamer (Angelus Model 62H). Upstream processing includes an APV R-55 plate pack pasteurizer with hold tube and balance tank.

Inspection and coding systems include a Filtec FT50 level fill inspector and two Videojet 1610 inkjet coders for cans. Product is conveyed through an accumulation table and exit conveyors to a Kayat M349 wrap-around case packer (Serial #PTF-28-152-92), followed by an Arpac 105-TW-32 shrink wrapper and two Videojet 2360 coders for case labeling. Material handling is supported by Hytrol conveyors throughout the line. Final palletizing is performed by a Whallon CF-90 case palletizer. Previously operated at approximately 40 cans per minute.

Specifications

| Stock Number | 5991536 |

| Manufacturer | Various – See Description |

| Serial Number | Various – See Description |

| Line Speed | Approx. 40 cans per minute (CPM) |

| Product Type | Round metal cans, frozen food products |

| Materials of Construction | Construction Material Assumed stainless steel / food-grade |

| Basis | As Is, Where Is |

General Information

Frozen food can line designed for round metal cans, incorporating well-established equipment brands and integrated for end-to-end automation. Suitable for producers of canned vegetables, soups, sauces, or pet foods. The full system covers depalletizing, pasteurization, filling, inspection, coding, case packing, shrink wrapping, and palletizing—streamlining throughput and supporting moderate to high production environments.