Centrifuge, Flottweg Tricanter, Model Z3E-4/441, 2016, Stainless Steel, With Controls, #5991393

Centrifuge, Flottweg Tricanter, Model Z3E-4/441, 2016, Stainless Steel, With Controls, #5991393

Location:California

Available quantity:1

Description

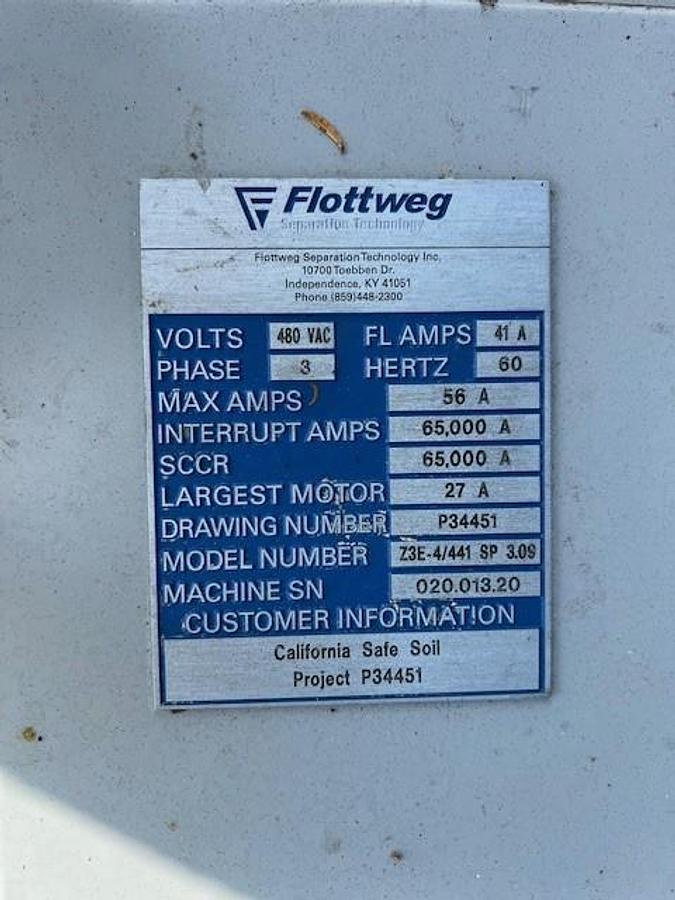

Flottweg Tricanter centrifuge, model Z3E-4/441 SP 3.09, serial number 020.013.20, manufactured in 2016. This three-phase horizontal decanter centrifuge provides continuous separation of solids and two immiscible liquid phases. Rated for 5250 RPM max bowl speed with 1.7 g/cm³ max sediment density, 300mm bowl ID, and 171mm discharge diameter. Operating temperature rated at 0–100°C. Features tungsten carbide and chilled cast bushing seals with scroll protection. Equipped with a 10 HP, 215T scroll drive motor rated at 3600 RPM. Includes stainless steel construction and a two-door programmable control panel. Control system includes Micrologix PLC, six ABB components, one AB Powerflex 40, two Lenze AC Tech drives, and one PanelView HMI. Electrical specifications: 460V, 3-phase, 60Hz. Includes pallet of lubricants. Previously used in a food-waste processing facility. Serial number 020.013.20.

Specifications

| Stock Number | 5991393 |

| Manufacturer | Flottweg |

| Model | Z3E-4/441 |

| Year | 2016 |

| Serial Number | 020.013.20 |

| Measurements | 10” diameter X 42” long (Estimate) |

| Type | Tricanter, 3-phase decanter centrifuge |

| Materials of Construction | Stainless Steel |

| Max Bowl Speed | 5,250 RPM |

| Max Sediment Density | 1.6 kg/dm³ |

| Drive System | Dual motor with VFD |

| Power Requirements | 480 VAC, 3-Phase, 60 Hz, 41 FLA |

| Previous Use | Food-waste processing |

| Basis | FOB |

General Information

Manufactured by Flottweg, a global leader in high-performance industrial separation systems. This Tricanter centrifuge is well-suited for food, beverage, chemical, and waste processing industries, particularly where three-phase separation of liquids and solids is critical. The robust 316 stainless steel construction ensures durability in corrosive environments. Touchscreen interface and integrated VFD controls support easy operation and process optimization.