Hopper, 85 CF, Stainless Steel, Receiving Bin, Ribbon Agitated, Auger Discharge, #5991688

Hopper, 85 CF, Stainless Steel, Receiving Bin, Ribbon Agitated, Auger Discharge, #5991688

Location:Chowchilla, CA

Available quantity:1

Description

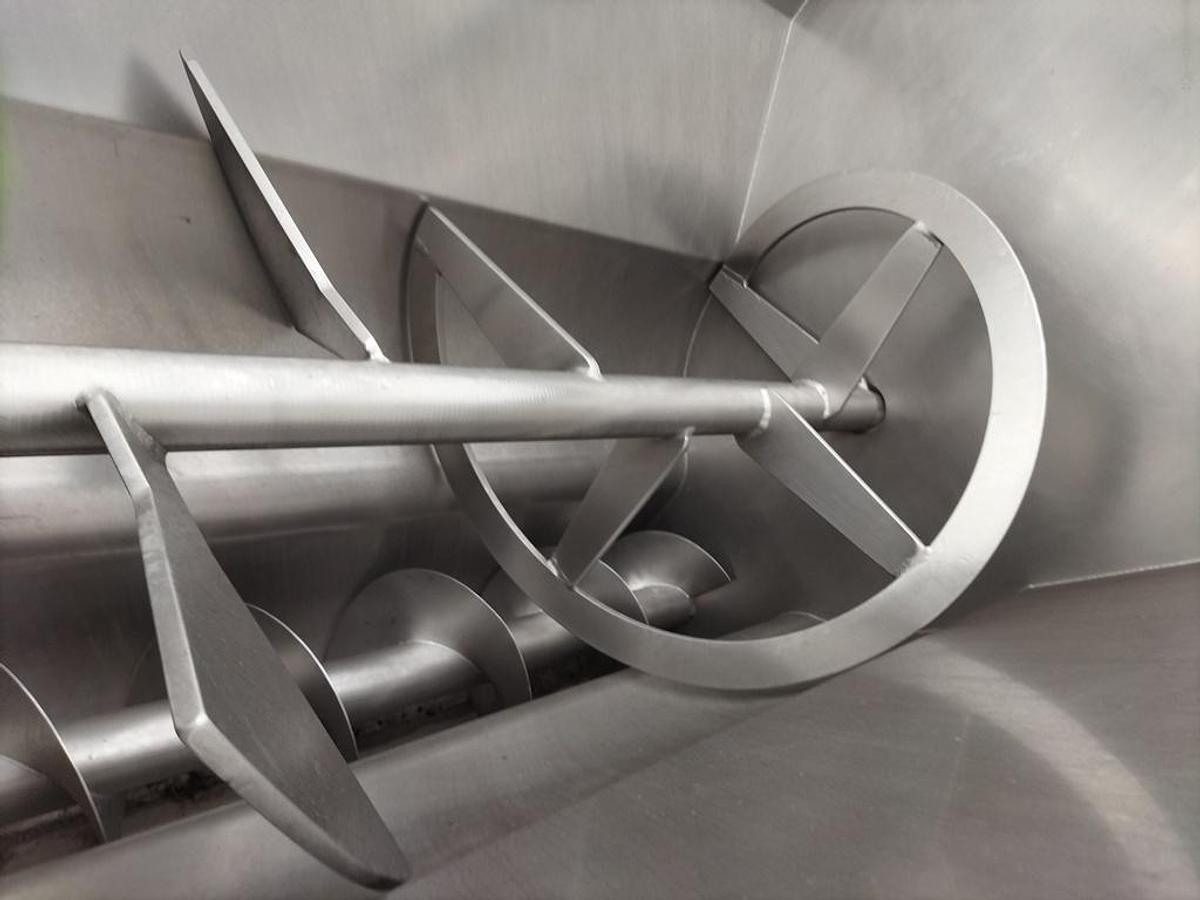

AMFEC Model 610 tainless steel receiving bin with an approximate capacity of 85–90 cu ft, designed for controlled intake and discharge of bulk materials. Unit is equipped with an internal ribbon agitator and paddle-style flow assist. Hopper includes a rectangular trough measuring approximately 13" x 13", with overall hopper dimensions of approximately 47" W x 5' L x 5' deep at the high end and 47" deep at the low end. The ribbon agitator is constructed with a 3" diameter shaft and 1/4" thick x 3-1/2" wide ribbon flights on an 11" pitch, with (2) internal paddles measuring approximately 1/4" thick x 13" L x 15" W. Material discharges through a 13" x 14" outlet into an inclined stainless steel auger featuring a 12" diameter screw mounted on a 3" shaft, elevating product to an approximate discharge height of 54". Unit is mounted on a rigid frame with adjustable leveling feet and is designed as a receiving and surge bin with flow-assist and metered discharge.

Specifications

| Stock Number | 5991688 |

| Manufacturer | AMFEC |

| Model | 610 |

| Serial Number | 9611100 |

| Cubic Feet | 85 cu ft (Estimate) |

| Materials of Construction | Stainless Steel |

| Hopper Dimensions | Approx. 47" W x 5' L x 5' deep |

| Trough Dimensions | Approx. 13" x 13" |

| Auger Diameter | 12" |

| Auger Shaft Diameter | 3" |

| Discharge Height | Approx. 54" |

| Basis | FOB |

General Information

Ribbon-agitated receiving bins are commonly used in food, chemical, and industrial bulk handling applications where reliable intake, surge capacity, and controlled feeding are required. The combination of internal ribbon agitation and inclined auger discharge allows difficult or semi-cohesive materials to be conditioned prior to transfer, improving feed consistency to downstream equipment such as weigh fillers, baggers, extruders, or continuous processing systems. Stainless steel construction supports washdown environments and sanitary processing requirements.