Bottling Line, 400 BPM, US Bottlers Filler, Krones Labelers, Fuji Intersleeve, Kisters Packer, #5991610

Bottling Line, 400 BPM, US Bottlers Filler, Krones Labelers, Fuji Intersleeve, Kisters Packer, #5991610

Location:American Canyon, CA

Available quantity:1

Description

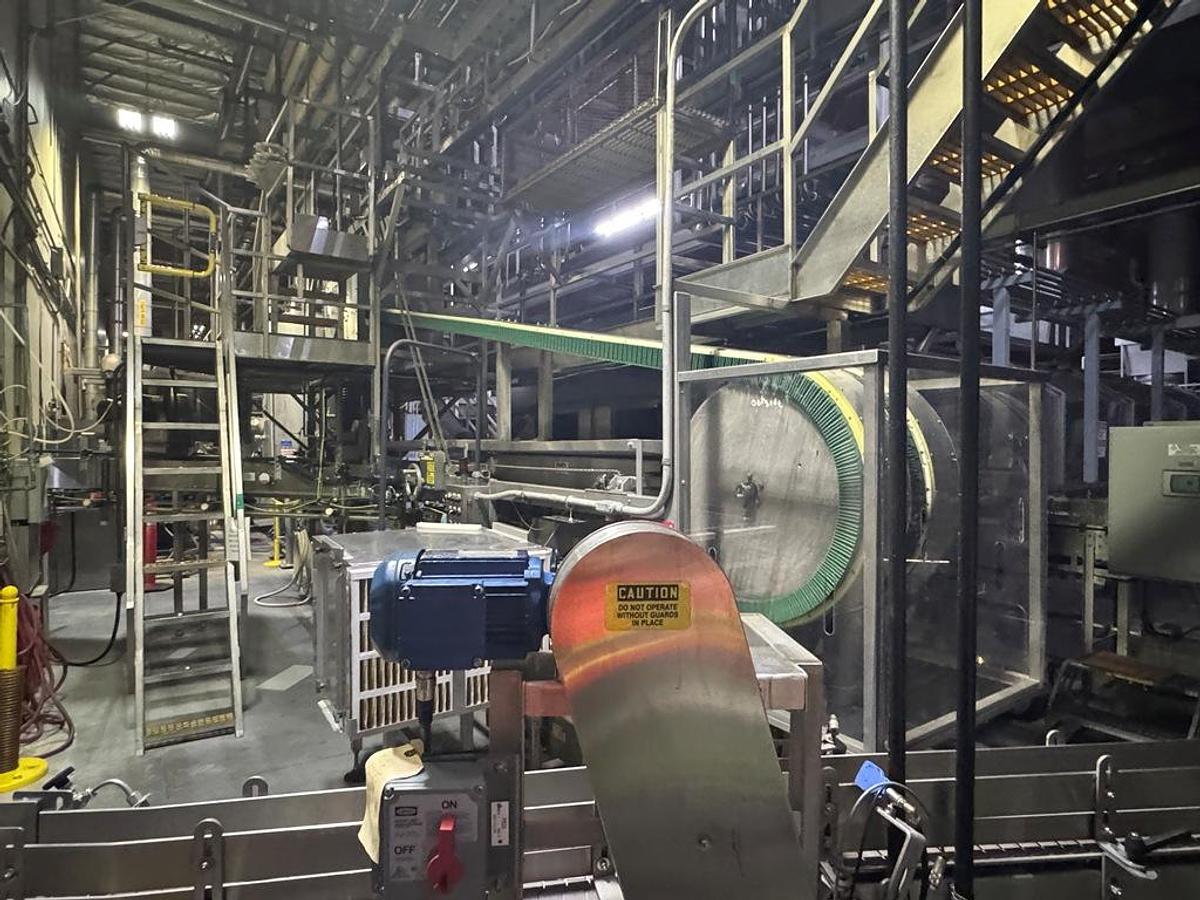

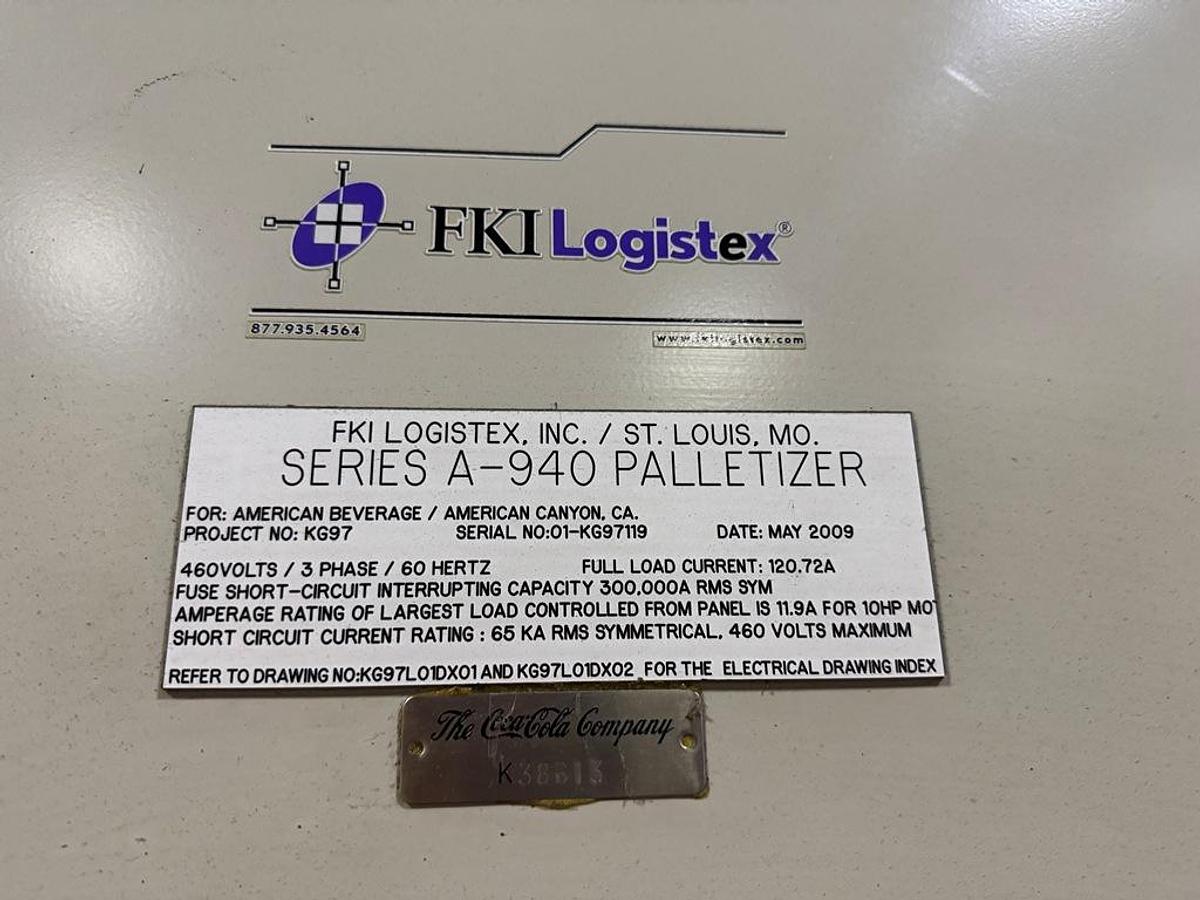

PET bottling and packaging system rated approximately 400 bottles per minute. Includes a US Bottlers Model PGF-64 pressure gravity filler with 16-head capper and Aidlin cap feeder. Upstream handling provided by a Sentry Z-Flow depalletizer (Model 1517) and low-pressure air conveyors with ionized air rinser. The labeling area features Krones Pronto Modul 18-head labeler and Krones Canmatic 18 wrap-around labeler (with Garantomatic sleeve applicator and steam tunnel). Line includes Kisters WSP 1-M Tray packer / shrink wrapper, Alvey Model 942 palletizer, and Cousins Hercules 7100-95-0HA stretch wrapper. Quality control by Silgan vision inspection and Filtec FT-50 gamma level inspection systems. Integration by J&M and Sentry with Allen-Bradley PLC controls. Line also includes pasteurizer skid and Feldmeier 1,500-gallon stainless tank for hot-water recovery. Configured for 0.5 L, 18 oz, 20 oz, and 28 oz PET bottles.

Offered with 2021 Douglas Spectrum 4-Sided tray packer with Nordson ProBlue glue system - Available separately Item #

Specifications

| Stock Number | 5991610 |

| Manufacturer | US Bottlers |

| Model | PGF-64 |

| Rated Speed | 400 BPM |

| Filler/Capper | US Bottlers PGF-64 w/ 16-Head Capper (Serial 149) |

| Cap Feeder | US Bottlers Waterfall Style for 38 mm Caps |

| Depalletizer | Sentry Z-Flow 44″ x 56″ (Model 1517) |

| Labelers | Krones Pronto Modul 18 & Canmatic 18 (2007), Fuji Intersleeve Sleeve Applicators (1997) |

| Palletizer | Alvey 942 (2009) |

| Stretch Wrapper | Cousins Hercules 7100-95-0HA |

| Vision Inspection | Silgan 51R56 (2017) |

| Level Inspection | Filtec FT-50 (2017) |

| Conveyors | Sentry Tabletop & Accumulation Tables (6′ x 14′ 6″, 8′ x 20′) |

| Basis | As-is, Where-is |

General Information

Krones, US Bottlers, and Douglas Machine equipment combine to deliver a proven medium-speed PET bottling line with excellent labeling accuracy and packaging efficiency. Designed for carbonated and non-carbonated beverages, this integrated system includes quality inspection, cooling, and heat-exchange utilities for a production solution from de-palletizing through pallet wrapping.