Bottling Line, 600–800 BPM, US Bottlers Filler, Sidel Labeler, Kisters TSP100V Shrink Wrapper, #5991609

Bottling Line, 600–800 BPM, US Bottlers Filler, Sidel Labeler, Kisters TSP100V Shrink Wrapper, #5991609

Location:American Canyon, CA

Available quantity:1

Description

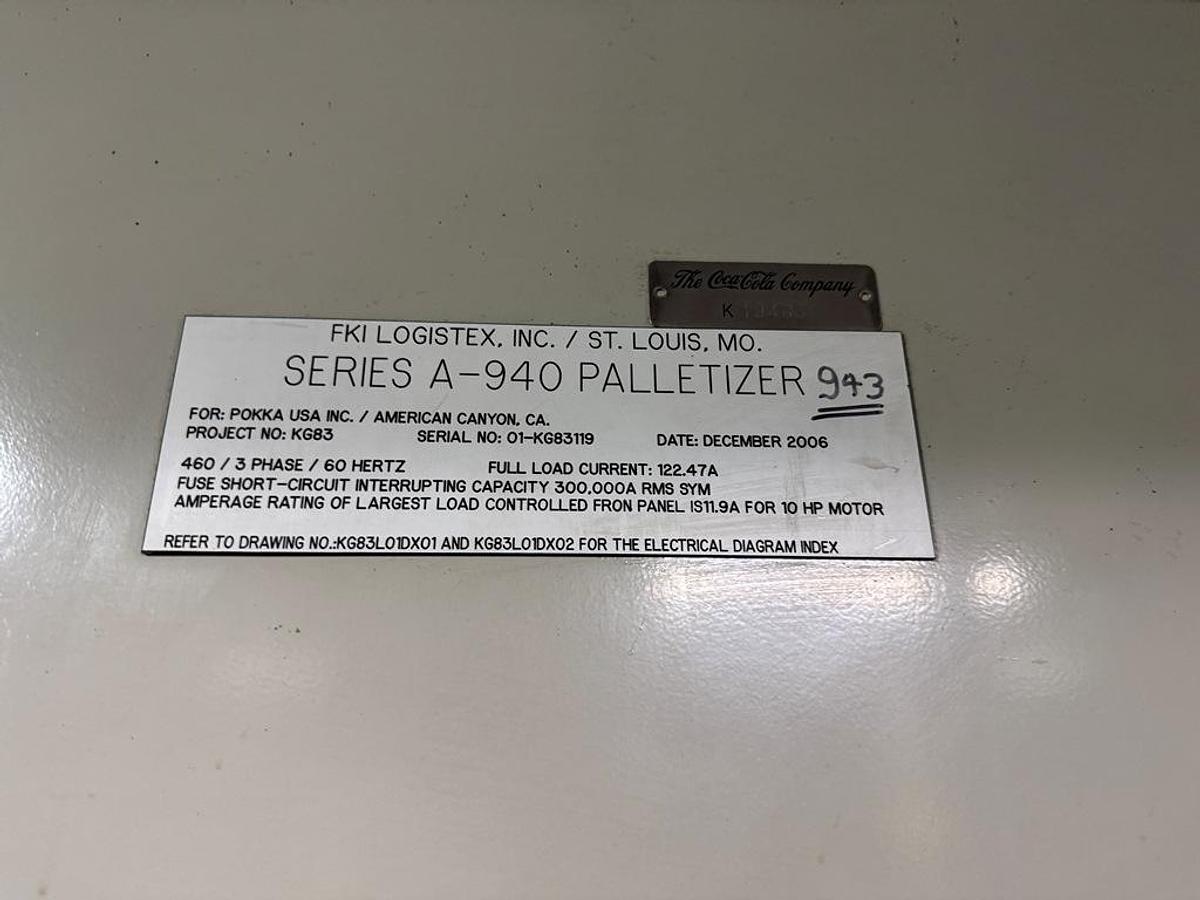

PET bottling and packaging system rated 600–800 bottles per minute. Features US Bottlers Model PG-96-120 96-valve pressure gravity filler with Zalkin 28-head capper, Aidlin Model CF 20 24 cap feeder, and Sentry rinser and conveyor system. Dual Sidel Model 35SE 24T/SM HH3 S1/E1 SX hot melt labelers (2018) provide high-speed labeling. Packaging section includes Kisters Model TSP100V tray packer/shrink bundler with Nordson ProBlue 12 glue unit, Alvey Model 943 palletizer, and Cousins Hercules 7100-95-OHA stretch wrapper. Quality control equipment includes Filtec FT-50 gamma level inspectors, Silgan 51R56 vision inspection, and Videojet 1560 coding systems. Ancillary equipment includes EC Nelson 15102CWS cooling water system, Alfa-Laval plate heat exchanger, and pasteurizer skid with hot water system. Fully integrated by J&M Systems with Allen-Bradley controls.

Specifications

| Stock Number | 5991609 |

| Manufacturer | US Bottlers |

| Model | PG-96-120 |

| Rated Speed | 600–800 BPM |

| Filler/Capper | US Bottlers PG-96-120 with Zalkin 28-Head Capper (1994) |

| Cap Feeder | Aidlin CF 20 24 (1994) |

| Labeler | Sidel 35SE 24T/SM HH3 S1/E1 SX (2018) |

| Case Packer/Shrink Wrapper | Kisters TSP100V (2006) |

| Palletizer | Alvey 943 (2006) |

| Stretch Wrapper | Cousins Hercules 7100-95-OHA |

| Vision Inspection | Silgan 51R56 (2015) |

| Level Inspector | Silgan 51R56 (2015) |

| Coders | Videojet 1560 / Markem 5000 |

| Controls | Allen-Bradley / J&M Integration |

| Basis | As-is, Where-is |

General Information

US Bottlers, Sidel, and Kisters are recognized leaders in reliable high-speed bottling systems. This fully automated PET line offers synchronized filler, labeler, and packaging modules engineered for beverage production efficiency. The inclusion of inline quality inspection, cooling, and water treatment systems provides a beverage packaging solution with flexibility for carbonated or still products.