Bottling Line, Chinese-Made, 2-Head Servo Filler, Capper, Labeler, Jacketed Hopper, Conveyors, #

Bottling Line, Chinese-Made, 2-Head Servo Filler, Capper, Labeler, Jacketed Hopper, Conveyors, #

Location:Canada

Available quantity:1

Description

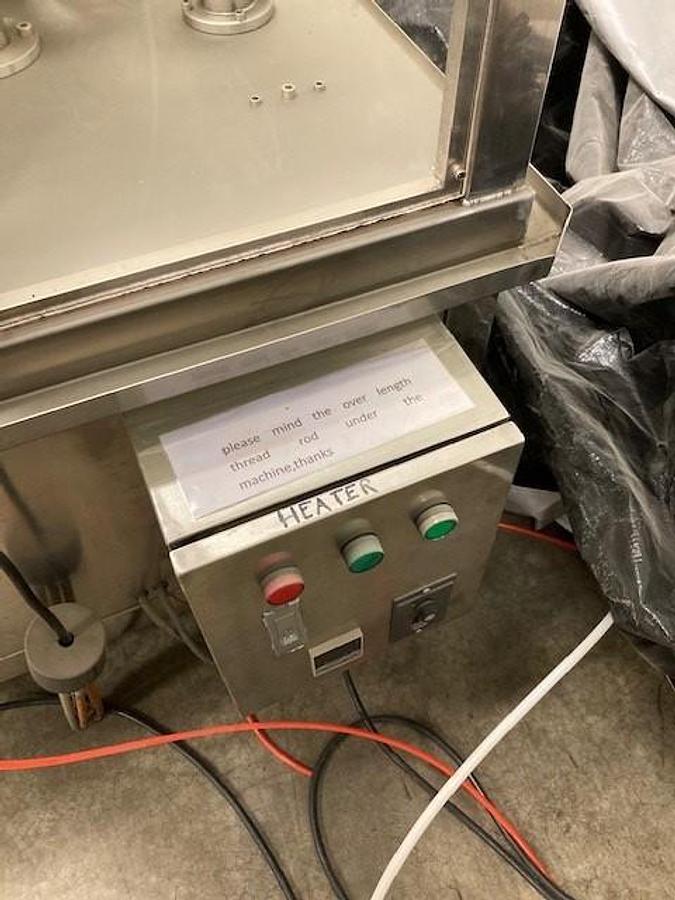

Fully integrated automatic bottling line. Features include a 2-head servo-driven filler with touchscreen control, pneumatic diaphragm pump, heated stainless steel hopper with mixer, automatic cap feeder with sorting bowl, capping system with mechanical arms, and automatic round bottle labeling machine (GZWS-08657). Includes entry and exit conveyors with accumulation turntables. Designed for cylindrical bottles and suitable for hot-fill liquid products such as oils, tinctures, and beverages. Clean, complete, and in good physical condition. Manuals and system diagrams included.

Specifications

| Stock Number | 5991476 |

| Manufacturer | Guangzhou Wanshun |

| Model | GZWS-08657 Labeler |

| Filler | 2-head servo-driven filler (up to 250 ml) |

| Product Feed | Pneumatic diaphragm pump |

| Hopper | Jacketed and heated with mixer (electric controls) |

| Capper | Automatic cap sorter and torque screw capper |

| Labeler | GZWS-08657 round bottle labeler, up to 50 BPM |

| Controls | HMI touchscreens on filler and labeler |

| Conveyors | Stainless steel infeed and outfeed conveyors |

| Accumulation | Turntables at both entry and exit |

| Electrical | 220V, single-phase |

| Basis | FOB Canada |

General Information

This turnkey Chinese-made bottling line offers automated filling, capping, and labeling for cylindrical containers in the food, cosmetic, supplement, or chemical sectors. The servo-controlled dual-speed filler provides volume precision and flexibility across different bottle sizes. A heated stainless hopper with integrated mixing supports hot fill applications. Mechanical cap placement and screw-on torque capping are managed by integrated vibration and pneumatic systems. Final-stage labeling is handled by the GZWS-08657 round bottle labeler, capable of up to 50 BPM with high accuracy. Ideal for businesses seeking an economical, mid-speed automated bottling solution.