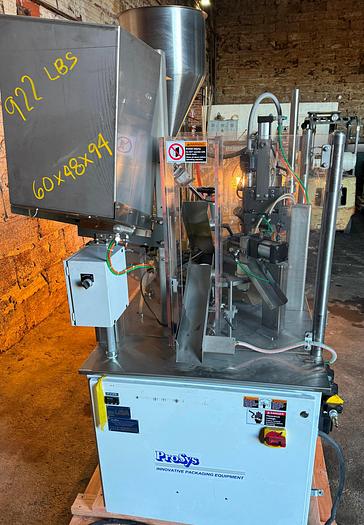

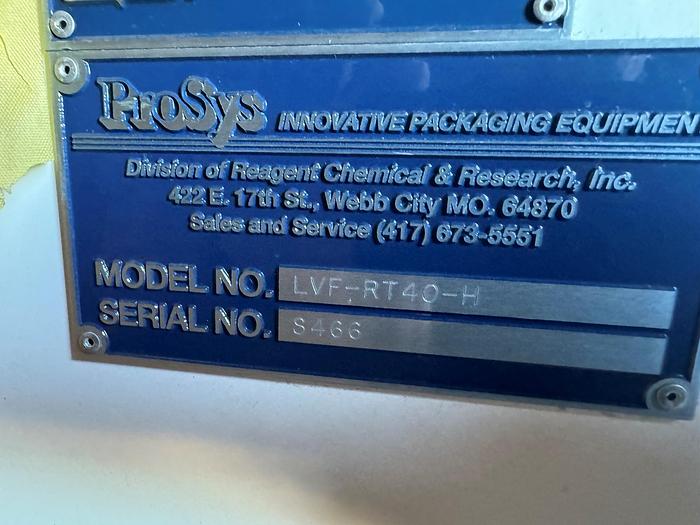

Filler, Tube, 12-Station, ProSys Innovative, Model LVF-RT40-H #S745364

Filler, Tube, 12-Station, ProSys Innovative, Model LVF-RT40-H #S745364

Location:Brisbane, CA

Available quantity:1

Description

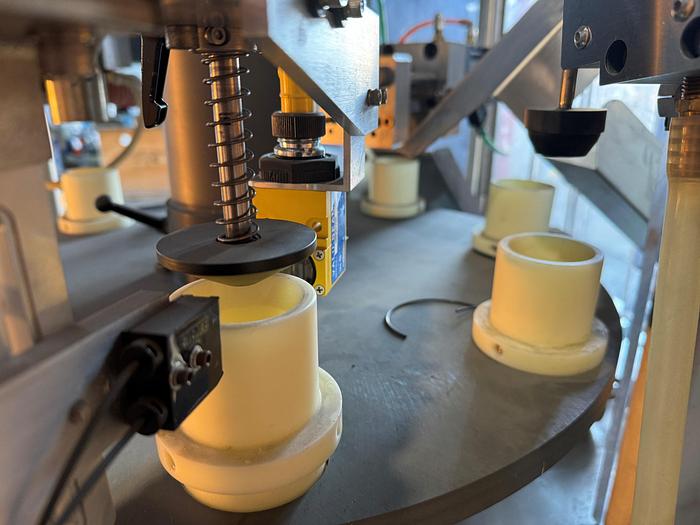

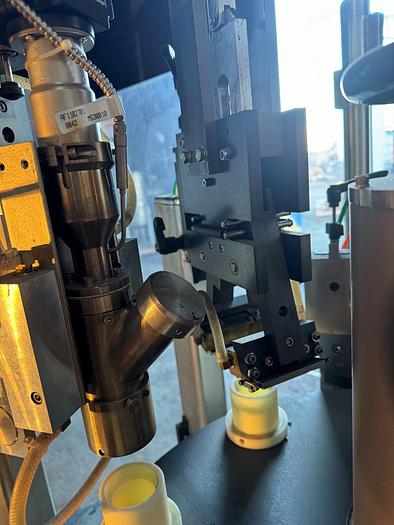

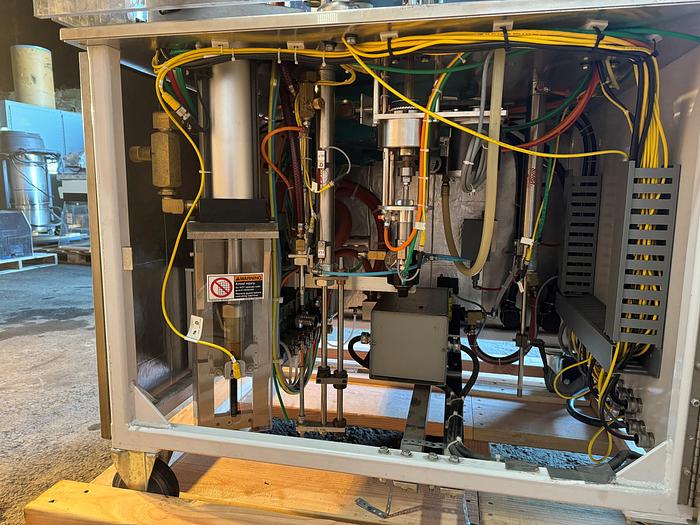

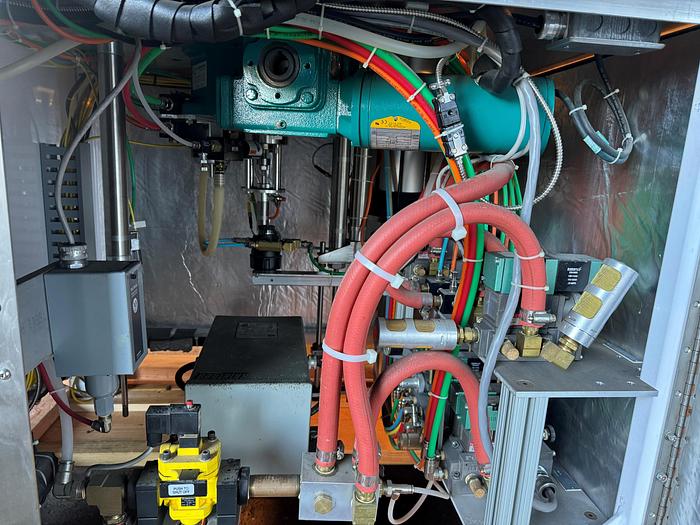

Prosys Innovative Packaging Model LVF-RT40-H Rotary Squeeze Tube Filling and Sealing system with 12-station indexing turntable. System includes tube feeding station to turntable with overhead arm to fully open tubes, stainless steel liquid dose filler with approx. 1/2" diameter opening, heat seal jaws and code station with top trim. Originally used at pharmaceutical facility. Serial number S466.

Specifications

| Stock Number | S745364 |

| Manufacturer | ProSys |

| Model | LVF-RT40-H |

| Serial Number | S466 |

| Stations | 12 |

| Materials of Construction | Stainless Steel |

| Previous Use | Pharmaceutical Packaging |

| Filler Type | Tube Filler, Sealer and Coder |

| Basis | FOB |

General Information

Manufacturer Details:

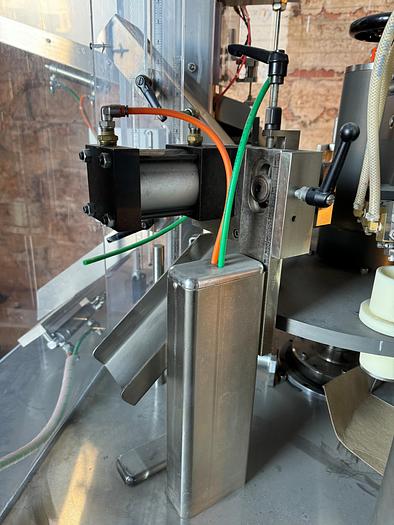

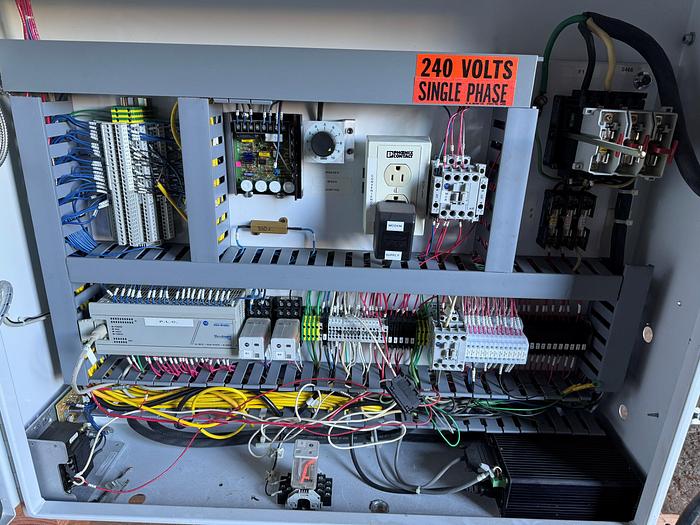

The ProSys Model LVF RT40H Rotary Automatic Squeeze Tube Filler is a single head tube filler designed for metering low viscosity materials into a plastic tube to be heat sealed. The machine is electric/pneumatic operated, designed for operation in a non-hazardous location. The pneumatic devices are controlled by separate air solenoid valves and regulators. The regulators supply air to electric solenoid valves, which direct the air to the pneumatic devices at each station. Flow controls are included on many of the air cylinders to control speed of the cylinder. A programmable logic controller controls the machine. The controller receives sensor inputs from devices on the stations (limit switches, photo eyes or proximity sensors), and turns on and off outputs (solenoid valves or relays) according to the controller program. An operator

interface provides information to the operator, allows input from the operator to select options and tune the machine for product variables. The operator places empty tubes onto the loading ramp, where they are automatically fed and loaded into the dial. The rotary dial indexes the tubes through the machine to be filled, sealed, trimmed and unloaded. The customer is to provide a means to handle the tubes once they exit

the ProSys filler.