Flash Dryer, GEA, Minerals or Biomass Drying, 27,000 lbs/hr water evap rate - C745152

Flash Dryer, GEA, Minerals or Biomass Drying, 27,000 lbs/hr water evap rate - C745152

Location:California

Available quantity:1

Description

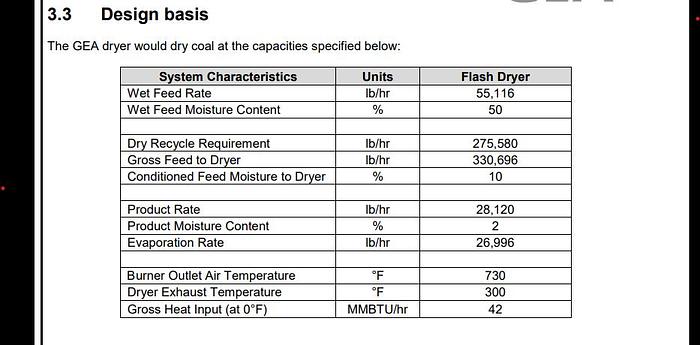

GEA Flash Dryer System rated for 26,996 pounds per hour water evaporation rate, Partial Gas Recycled system with Comenco Systems direct fired air heater, 42MM BTU/hr heat input. System takes wet material through 15 HP Lump Breaker and into 125 HP Double Paddle Mixer where it is mixed with dry recycle material from dryer. System includes (2) bag filters / dust collectors with rotary airlock valves, product falls into variable-speed augers. Auger feeds into 250 HP Disintegrator to break up agglomerated product. Wet product is introduced to high-speed Venturi where hot drying process air from the combustion chamber and is accelerated upwards into the Drying Column where the majority of the drying takes place. The drying air is drawn through the system by an 800 HP Recirculation Fan located downstream of the bag filters. Exhaust gas comprised of the products of combustion and evaporation is discharged from the drying circuit through the Bleed-off Damper. The excess gas is then sent to a Stack. Natural gas supply - 46,000 SCFH flow rate; Recycled air from dryer - 89,097 lbs/hr (211,745 ACFM); Heater outlet air - 247,504 lbs/hr (159,269 ACFM); combustion air flow - 24,500 lbs/hr (7,667 SCFM). Can be used for various minerals and biomass materials, such as dry spent distillers grains. Mild steel construction.

Unused System * New in 2019

Specifications

| Stock Number | C745152 |

| Manufacturer | GEA |

| Wet Feed Rate | 55,116 pounds per hour |

| Wet Feed Moisture Content | 50% |

| Dry Recycle | 275,280 pounds per hour |

| Gross Feed to Dryer | 330,696 lbs/hr |

| Product Rate (dry basis) | 27,558 lbs/hr |

| Product Moisture Content | < 2% |

| Evaporation Rate | 26,996 pounds per hour |

| Burner Outlet Temperature | 720º Fahrenhit |

| Dryer Exhaust Temperature | 300º Fahrenheit |

| Basis | As-is, Where-Is |

General Information

The GEA dryer offers efficient and reliable drying performance, ensuring that the minerals are dried to the desired moisture content. It utilizes a flash drying process to rapidly evaporate moisture from the wet feed. The dryer's advanced design and precise temperature control enable it to achieve the specified product moisture content and meet the required evaporation rate. With a high burnout temperature and effective exhaust temperature control, the dryer optimizes energy consumption while maintaining product quality. The GEA dryer is a trusted solution for coal drying applications, providing consistent results and contributing to enhanced operational efficiency.